BIS Certification (ISI Mark) for Plastic Feeding Bottles (IS 14625)

Welcome to ASC Group’s comprehensive guide on obtaining BIS Certification for Plastic Feeding Bottles with the ISI Mark IS 14625. This certification is essential for manufacturers who are committed to meeting India's rigorous safety and quality standards for plastic feeding bottles. The BIS (Bureau of Indian Standards) Certification serves as a benchmark, ensuring that products adhere to national standards.

Featuring the ISI Mark, it represents compliance with the specific safety norms encapsulated in IS 14625, which is pivotal for maintaining product integrity and consumer trust. By obtaining this certification, manufacturers not only meet mandatory regulatory requirements but also enhance their market credibility, as the ISI Mark is a symbol of reliability and quality assurance that resonates with consumers.

Importance of BIS Certification for Plastic Feeding Bottles

Obtaining BIS certification for plastic feeding bottles is not just a regulatory step but a significant enhancement to your product’s market appeal:

- Safety Compliance: Ensures that the feeding bottles meet all required safety norms, protecting infants from potential harm.

- Market Credibility: Certified products are often preferred in the marketplace, enhancing your brand’s reputation and credibility.

- Regulatory Necessity: Compliance with Indian safety regulations is mandatory for selling baby bottles in India, making certification essential.

Procedure for Obtaining BIS Certification for Plastic Feeding Bottles (For Domestic Manufacturers)

Documentation

Begin the certification process by providing comprehensive details about your manufacturing unit. This includes information on your facility's registration, ownership, and the Inhouse Test Reports Laboratory equipment. Additionally, you must submit product details such as specifications to confirm the scope of the license, ensuring alignment with IS 14625 compliance for plastic feeding bottles.

Pre-Testing of the Sample

- Submit Samples: Send plastic feeding bottle samples to a BIS-recognized laboratory for pre-testing to verify adherence to safety and quality standards.

- Wait for Results: The laboratory conducts rigorous tests to ensure compliance with IS 14625 safety standards for baby bottles and provides the test report via the Laboratory Information Management System (LIMS).

Apply for an Application

After securing the test report, submit an application through the BIS Portal. This application must include all required documents and the government fee. The application process is crucial for manufacturers to demonstrate their commitment to meeting the quality standards for feeding bottles.

Factory Inspection

- On-Site Inspection: A BIS officer conducts a factory inspection to evaluate the production processes and quality control measures in place, ensuring they are up to the standard required for plastic feeding bottle manufacturers and BIS compliance.

- Compliance Verification: The inspection verifies if the manufacturing practices align with the claims made in the application.

- BIS Officer Seal the Sample for Testing: The BIS officer will seal a sample during the inspection for further testing to confirm compliance.

Issuance of License

Upon successful documentation and test result review, which includes the audit findings, BIS officials will issue the BIS License. This license is a key indicator of a manufacturer’s adherence to the Indian safety standards for feeding bottles.

Post Test Report

Finally, the manufacturer will receive a post-test report of the sealed samples from the BIS-recognized lab. The license will remain operative as long as the test reports are found satisfactory across all testing parameters, ensuring continuous compliance with BIS certification requirements for baby bottles.

Timeline for Obtaining BIS Certification for Plastic Feeding Bottles (for Domestic Manufacturers)- 30 to 35 Working Days

You can also check "BIS Certification for Room Heaters"

Price/Cost for Obtaining BIS Certification for Plastic Feeding Bottles (For Domestic Manufacturers)

|

Registration Fees |

Renewal Fees |

Inclusion Fees |

|

1. Application Fee - INR 1000/- 2. Inspection Fee - INR 7000/- 3. License Fee - INR 1000/- 4. Marking Fee - Depends on the Product 5. Sample Testing Charge - Depends on the product |

1. Renewal Application Fee - INR 1000/- 2. Marking Fee - Depends on the product 3. License Fee - INR 1000/- |

1. Application Fee - INR 5000/- 2. Sample Testing Charges - Depends on the Product 3. Inspection Fee - INR 7000/- (if applicable |

Documents Required for BIS Certification for Plastic Feeding Bottles (For Domestic Manufacturers)

- Premises document

- GST certificate

- Copy of partnership deed or MOA copy

- Udyam Aadhar

- Process flow chart, if applicable

- Aadhaar card of business owner

- Trade Mark certificate

- List of Raw Material

- Test Certificate/Lab report of Raw Materials

- Process flow chart

- Detailed production Process description

- Location plan of the factory from nearest Airport/Railway Station or Bus Stand

- Layout of Plant

- List of Machinery

- QCI details

- List of Equipment

- Calibration Certificates copy, if available

Also, Check "BIS Certification (ISI Mark) for Sports Footwear"

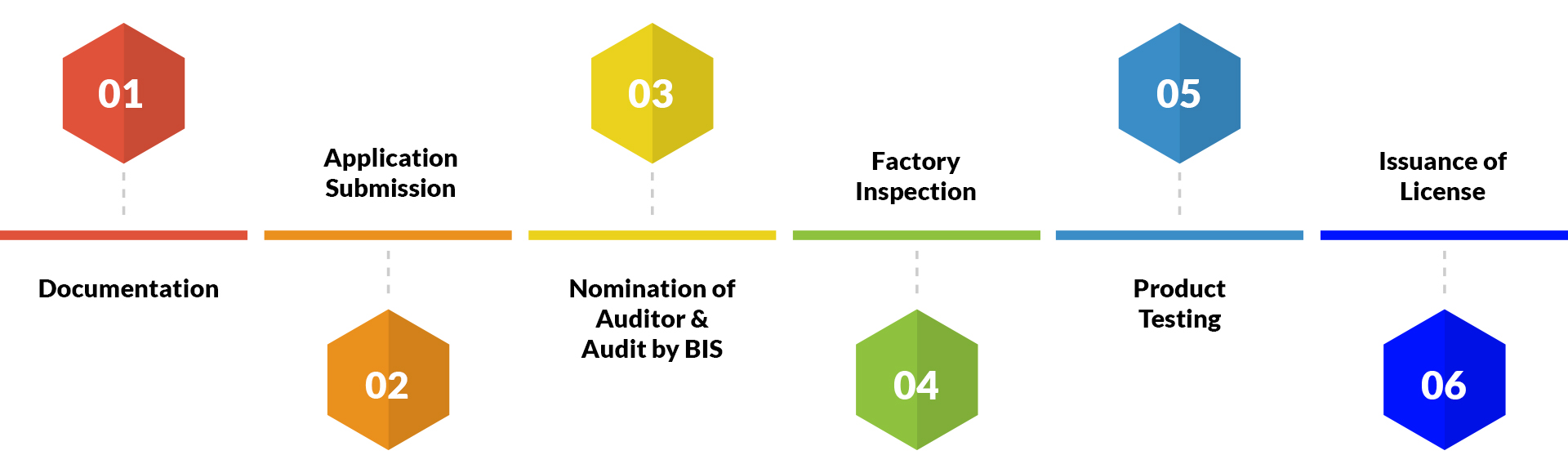

Procedure for Obtaining BIS Certification for Plastic Feeding Bottles Under FMCS (For Foreign Manufacturers)

Documentation

- Facility Details: Provide comprehensive information about the manufacturing unit, including registration and ownership details.

- Equipment and Testing Facilities: Outline the in-house laboratory equipment available for preliminary product testing.

- Product Specifications: Submit detailed specifications of the plastic feeding bottles to confirm adherence to the quality standards for feeding bottles.

Application Submission

- Documentation Submission: Along with the application on the BIS Department, submit all necessary documentation that demonstrates IS 14625 compliance for plastic feeding bottles.

- Fee Payment: Include the required government fee associated with the BIS certification process.

Nomination of Auditor and Audit by BIS

- Auditor Nomination: The BIS will nominate an auditor who will initially review the application and documentation to ensure compliance with Indian safety standards for feeding bottles.

- Preliminary Audit: The auditor assesses the readiness for the upcoming factory inspection.

Factory Inspection

- On-Site Evaluation: Conducted by a BIS officer or nominated auditor to scrutinize the manufacturing processes and quality control measures.

- Compliance Check: Ensure that the production of plastic feeding bottles aligns with the safety standards for baby bottles.

Product Testing

- Sample Testing: Send product samples to a BIS-recognized lab for comprehensive testing.

- Testing Parameters: Check for compliance with established safety and quality benchmarks essential for plastic feeding bottle manufacturers and BIS compliance.

Issuance of License

- Review of Findings: BIS reviews the documentation, audit reports, and test results.

- License Grant: If compliant with the BIS standard IS 14625, a certification license is issued, validating the plastic feeding bottles' safety and quality.

Timeline for Obtaining BIS Certification for Plastic Feeding Bottles under FMCS (for Foreign Manufacturers) - 180 Working Days

Price/Cost for Obtaining BIS Certification for Plastic Feeding Bottles Under FMCS (For Foreign Manufacturers)

|

Registration Fees |

Renewal |

Inclusion |

|

1. Application fee - (USD 20 per Application) |

1.Renewal Application fee - USD 20 |

1. Application fee - 100 USD |

|

2. Visit charges (man day charges for Auditor) - BIS (USD 100 per day) (100 x 6 = USD 600) |

2.Marking fee - Depends on the production |

2. Sample Testing Charges - Depends on the product |

|

3. Auditor's Per Diem charges (Include Stay & Local expenses in foreign country) - USD 400 per day for European Countries and USD 300 per day for Non SAARC countries and USD 250 per day for SAARC countries. ( This is to be paid for 3 days only) |

3.License fee - USD 20 |

|

|

4. Travel Expenses (include Visa, insurance, Flight etc) - BIS (As per actual) |

||

|

5. Travelling Expenses (Airfare, Visa, Stay and other expenses) of consultant, only if travelled along with BIS Auditor - To be arranged by the manufacturer/applicant |

||

|

6. Consultant's Per Diem Charges (Only if travelled along with BIS Auditor) - USD 100 per Day |

||

|

7. License Fee - BIS (USD 20 per Application) |

||

|

8. Annual Minimum Markings Fees - As per Actual |

||

|

9. Bank Guarantee (To be given after Grant of License) - BIS (USD 10.000) (Refundable) |

||

|

10. Contingency charges (For BIS Auditor's India travel expenses) BIS (USD 150 per Application) |

||

|

11. Testing charges - As per Actual |

Documents Required for BIS Certification for Plastic Feeding Bottles Under FMCS (For Foreign Manufacturers)

- Name & Address Proof of Factory

- Name & Address Proof of Office

- Form V

- Air nomination form

- Authorization letter

- Location Map

- Layout of Plant

- List of Machinery

- List of Raw Material

- Test Certificate/Lab report of Raw Materials

- List of Testing Equipment

- Calibration Certificate of Test Equipment’s

- Brand details

- Degree of Quality Control In-charge

- Process flow chart, if applicable

- Process flow description

- Identity card of business owner

- Production Details

Must Check "BIS Certification for Packaged Drinking Water"

Advantages of BIS Certification for Plastic Feeding Bottles

Manufacturers who obtain BIS certification gain several tangible benefits:

- Enhanced Product Safety: Certification ensures that products meet high safety standards, reducing health risks to babies.

- Increased Market Access: Access to a wider market, both domestically and internationally, as certification builds trust.

- Compliance with Regulations: Adherence to national regulatory requirements, avoiding potential legal issues.

- Consumer Assurance: Assures consumers of the quality and safety of the bottles, influencing purchasing decisions.

- Competitive Edge: Sets your products apart from non-certified competitors, offering a significant advantage in the market.

How ASC Group Can Help

ASC Group specializes in facilitating the BIS certification process for manufacturers:

- Expert Consultation: Our experts provide insights and guidance on navigating the BIS standards.

- Documentation Support: We assist in preparing and organizing all necessary documents for submission.

- Testing and Compliance: Help coordinate testing procedures to ensure your products meet the BIS criteria.

- Liaison with BIS: Act as your liaison with BIS authorities to expedite the certification process.

FAQs

1. What is the ISI Mark IS 14625, and why is it necessary for feeding bottles?

The ISI Mark IS 14625 specifies the Indian Standard for plastic feeding bottles, essential for ensuring products are safe and free from harmful materials. It is mandatory for market entry in India.

2. What are the key safety standards for baby bottles in India?

Key standards include material safety, structural integrity, and chemical composition. These standards ensure that the bottles do not pose any health risks to infants.

3. How can manufacturers obtain BIS certification for feeding bottles?

Manufacturers need to apply to the BIS, provide necessary documents, undergo product testing, and pass facility inspections to obtain certification.

4. What are the costs involved in obtaining BIS certification for infant feeding bottles?

Costs include application fees, testing fees, and potential charges for consultancy and facility adjustments. The total can vary based on the scope of the project.

5. How long does it take to complete the BIS certification process for IS 14625 compliance?

The process typically takes a few months, depending on the readiness of the manufacturing facilities and the completeness of the documentation.

Leave a Reply